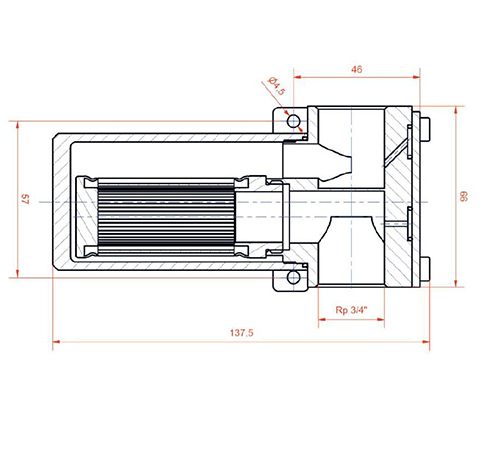

Stainless steel in-line filter LF 80-200

Dirt particles in coolants often result in clogging the small cooling channels, which render the mould inserts unusable. This maintenance-friendly stainless steel in-line filter LF80-200 offers a cost-effective and excellent protection against foreign particles, in particular for conformal cooling channels of injection moulds. The filter can be flanged to the mould or operated directly with temperature control units.

The high filter performance is based on a star-shaped folded stainless steel sieve that prevents the ingress of all particles > 200 μm into the cooling channel.

Versatile use

The filter is suitable for water-based or oil-based coolants with a flow rate of up to 80 l/min and offers versatile application possibilities in a temperature range of -10 to 260°C and a pressure of 16 bars.

Simple maintenance

The maintenance-friendly concept allows the filter insert to be easily removed and cleaned with compressed air, in an ultrasonic bath or using a high-pressure cleaner. The filter housing remains in the system circuit.

The LF80-200 can be delivered with an optional maintenance indicator.

All advantages at a glance:

- Cost-effective with high filter performance

- Simple maintenance and cleaning

- Suitable for high flow rates

- Large temperature range