Brazing makes it possible to combine different materials and properties in one component

Vacuum brazing, in particular, provides designers with more creative leeway. This allows them to develop new or enhanced functions with a high degree of innovation. The modular component design simplifies manufacturing processes and helps save costs. The scope of applications ranges from simple tools to high-tech components for the aerospace industry.

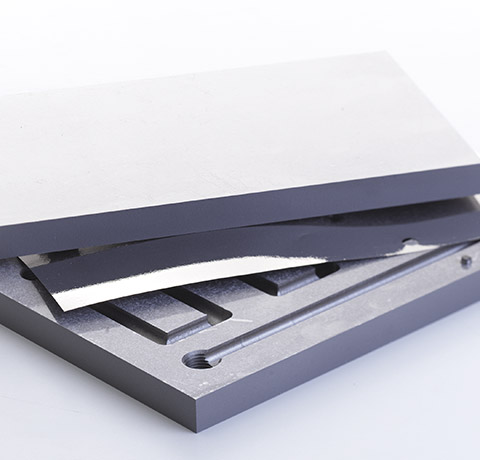

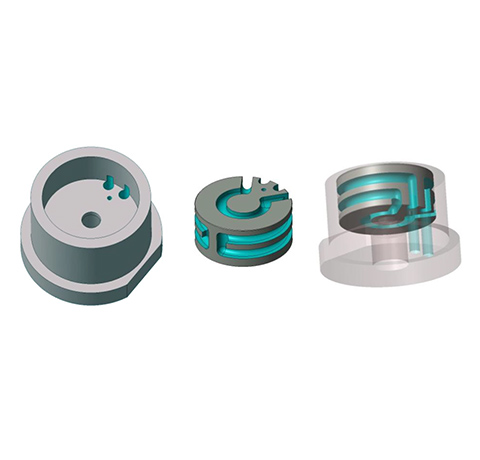

- Vacuum brazing of planar mould inserts

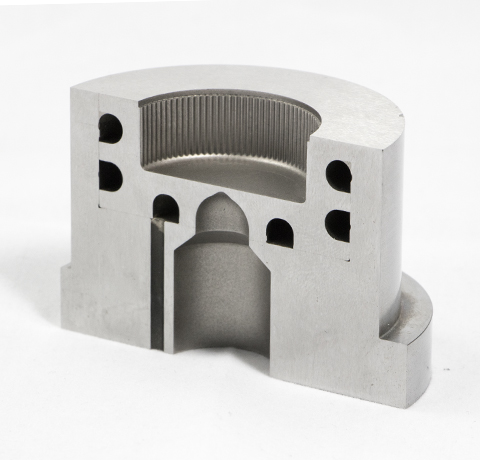

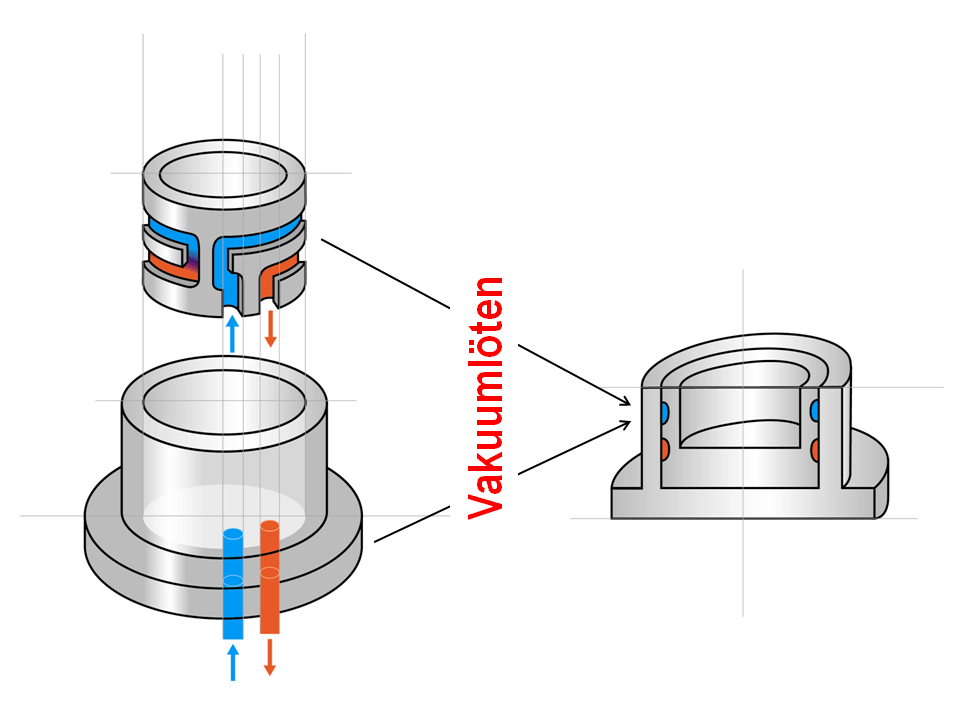

- Circumferential brazing of mould cores and feed bushes

- Soldering-in of cooling cores made of high-purity copper

- Vacuum brazing of different material combinations

Benefits:

- reproducible quality

- high strength, even at increased operating temperatures

- no flux required

- allows large components to be joined

- diverse material combinations

- minimal warping

- no oxidation or annealing

- hardening can be integrated in the process

Material groups:

- mild steel, stainless steel, super alloys, pure nickel

- copper and copper alloys

- titanium and titanium alloys

- tungsten carbide, high-performance ceramics, cBN, diamond

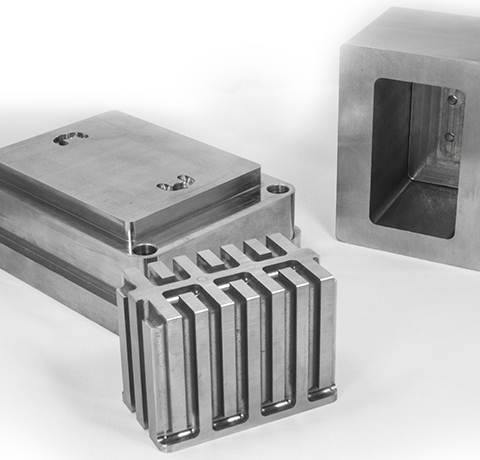

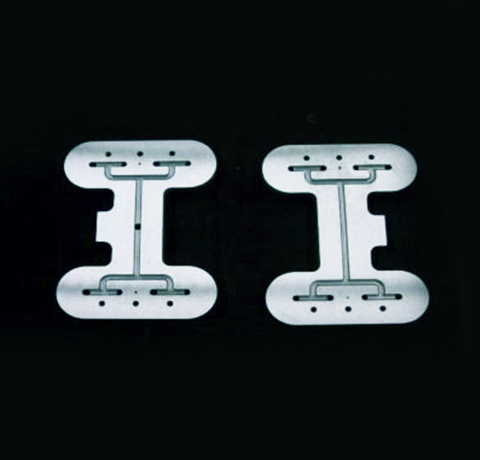

Production of blanks for brazing

Upon request, we can manufacture for you the blanks for brazing, taking into account the required design for vacuum brazing.

- Creating 3D data

- Preparing production drawings for blanks with dimensions and tolerances

- Manufacturing the blanks for brazing

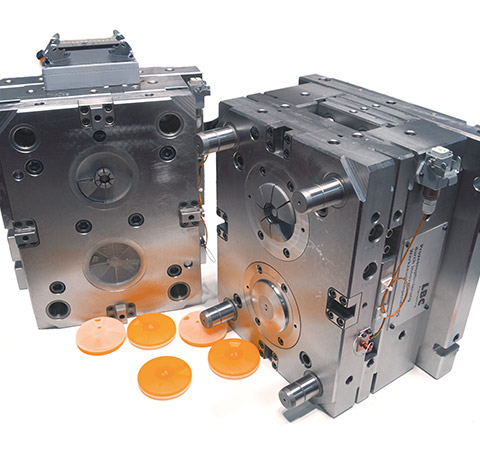

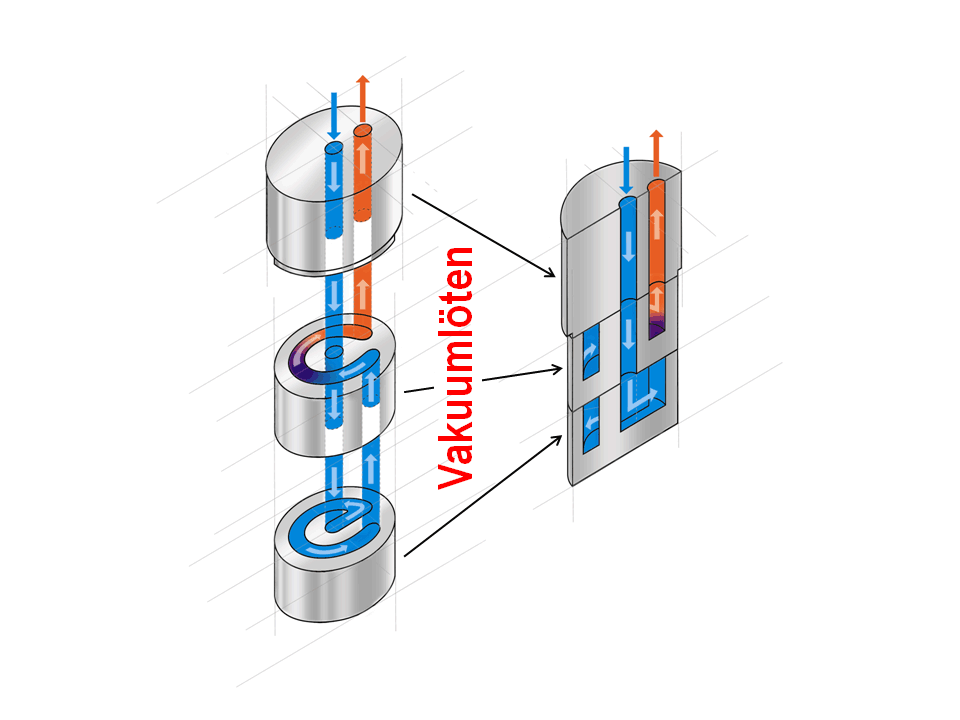

Combining vacuum brazing and additive manufacturing

The combination of these two processes creates unprecedented possibilities and benefits, allowing you to achieve maximum performance in temperature control of injection moulds and die-casting tools.

Talk to us!