iQtemp – the competence center for conformal cooling

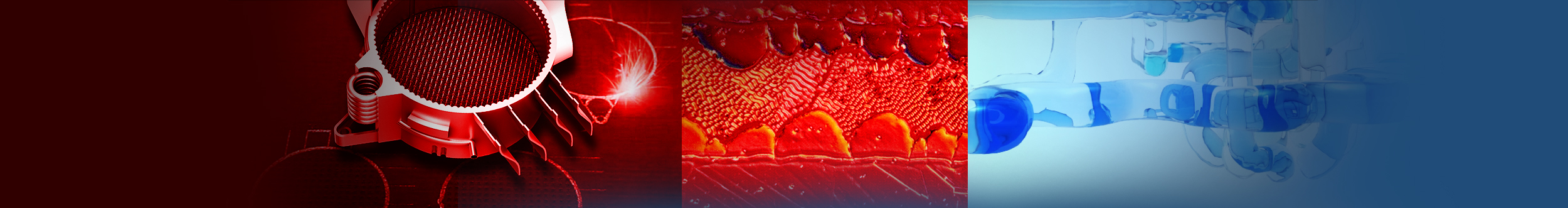

Mixing different technologies to achieve maximum performance in temperature control of injection moulds and diecasting tools. The combination of vacuum brazing and laser generation creates unprecedented possibilities and benefits.

iQtemp allows customers to choose from the following range of services the ones that suit their specific needs. One single contact provides you access to the experts for all the technologies applied in conformal temperature control. With a unique range of services and outstanding flexibility, we can offer you a tailored solution for temperature control of your mould inserts:

- Design and simulation of temperature control

- Creation of 3D data / production drawings

- Additive manufacturing

- Manufacturing semi-finished products (blanks for brazing / hybrides)

- Vacuum brazing and hardening, heat treatment

- Electron beam welding

- Corrosion protection coating

- Stainless steel in-line filter

iQtemp, located in Lüdenscheid /Germany, is a member of the hotset Group and the competence centre for conformal cooling and temperature control of injection and die casting tools. In addition to the design of optimized temperature control systems and simulation, iQtemp offers the implementation by different processes. These are currently additive manufacturing, vacuum brazing and electron beam welding. To complete the portfolio, customers can receive the corrosion protection coating of the temperature control channels on request, as well as a stainless steel in-line filter to protect the channels from contamination and closure.

In close cooperation with other experts of conformal cooling, such as software manufacturers, iQtemp offers the customer the unique benefit of receiving complete solutions for their tasks from one contact person. Our many years of expertise enable solution oriented, technology independent consulting and market proven implementation.

hotset is a leading supplier of state-of-the-art technology for all areas of industrial temperature control technology. We offer innovative product and system solutions for thermodynamic applications as well as a wide range of comprehensive outsourcing services.

Our role as a supplier and development partner is to support our customers in various industries such as plastics, surface and hot runner technology, toolmaking, foundry engineering, food technology, packaging technology and many others in the implementation and optimization of thermodynamic processes.